Test expertise, test labs and quality assurance

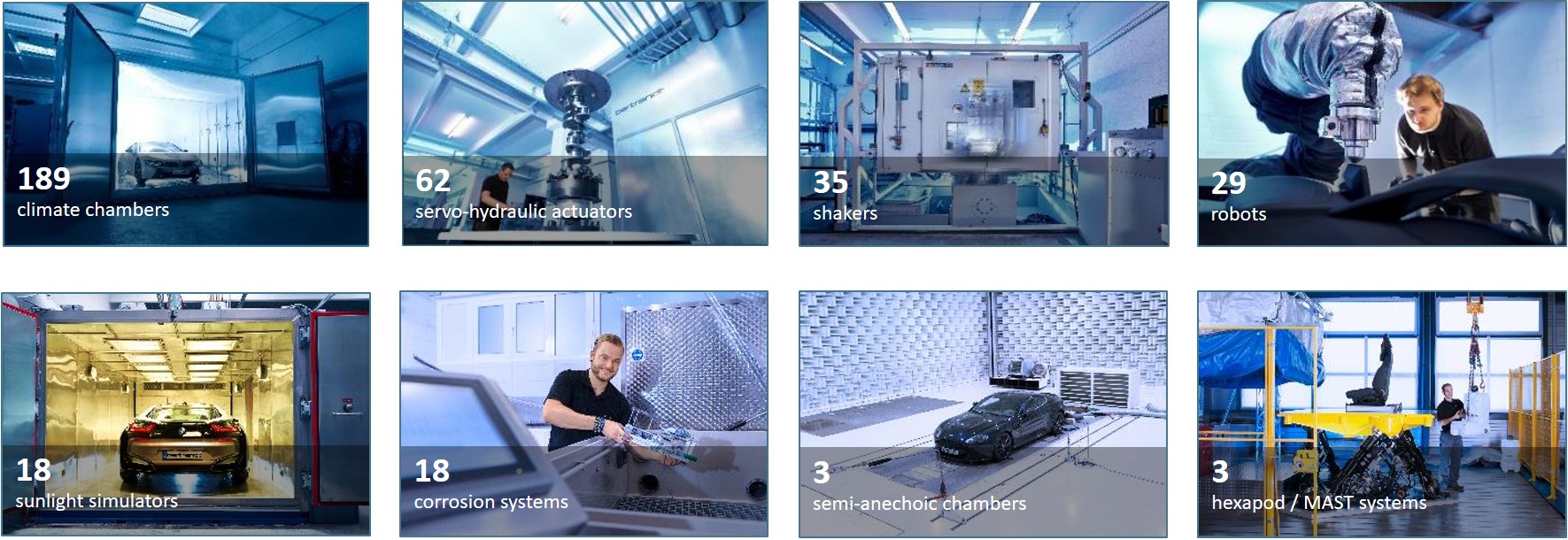

We are the pros where testing and quality are concerned – as proven by our wide range of testing services. Regardless of the sector, our expert teams work away at six sites in Germany putting your products through their paces, ensuring compliance with the highest international standards and the utmost quality. Whether it’s an environmental simulation, operational stability test or functional endurance trial: we offer you the right solution and method for your situation, accelerating the process of bringing your product or innovation to market. And we’re certain to be right nearby, too.